Renegotiating contracts with vendors may yield savings on supplies or services. The articles and research support materials available on this site are educational and are not intended to be investment or tax advice. All such information is provided solely for convenience purposes only and all users thereof should be guided accordingly. Finance Strategists has an advertising relationship with some of the companies included on this website. We may earn a commission when you click on a link or make a purchase through the links on our site.

Find the talent you need to grow your business

This calculation acts as a tool for timely reviews of spending, helping to trigger necessary adjustments in expense management in relation to changes in production or sales. Savvy factory managers use these strategies to control the cost of manufacturing in their facilities. Calculating the true cost of manufacturing takes a nuanced approach to certain changing factors and situational variations in production. Every manager should adjust the cost of manufacturing calculations based on the unique requirements of their service and the industries they serve. The general cost calculators below can be modified to suit specific applications.

Practical Application of Overhead Rates in Business

This article will guide you on how to effectively calculate predetermined overhead and also introduce how Sourcetable can simplify this process with its AI-powered spreadsheet assistant. Suppose the estimated manufacturing overhead predetermined manufacturing overhead rate formula cost is $ 250,000 and the estimated labor hours is 2040. Ahead of discussing how to calculate predetermined overhead rate, let’s define it. A predetermined overhead rate(POHR) is the rate used to determine how much of the total manufacturing overhead cost will be attributed to each unit of product manufactured. This allows businesses to capture the full cost of production in their accounting. Calculating the Predetermined Overhead Rate (POR) is a critical step in cost accounting, particularly in the manufacturing sector.

- Since complex tools are much more expensive to design and build than simple ones, these manufacturing expenses can only be justified when making parts that absolutely demand it.

- For some companies, the difference will be very minute or there will be no difference at all between different basis while for some other companies the differences will be significant.

- Hence, preliminary, company A could be the winner of the auction even though the labor hour used by company B is less, and units produced more only because its overhead rate is more than that of company A.

- Its integrated AI assistant not only computes results but also guides users through the methodology.

Calculating Overhead Rates: Formulas and Examples

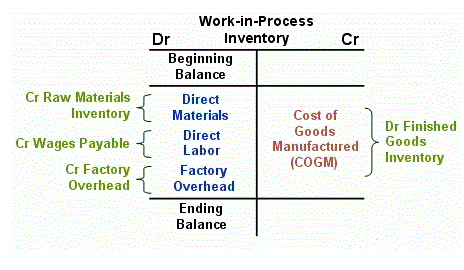

At the beginning of year 2021, the company Bookstime estimated that its total manufacturing overhead cost would be $268,000 and the total direct labor cost would be 40,000 hours. The actual total manufacturing overhead incurred for the year was $247,800 and actual direct labor hours worked during the year were 42,000. Calculating predetermined overhead rates is critical for accurately assigning manufacturing costs to products. The allocation base is the method cost accounting uses to allocate overhead costs, such as machine hours or direct labor hours.

Production Tooling

Additionally, experimenting with AI-generated data helps in understanding fluctuating scenarios without risking real financial inputs. There are a few business expenses that remain consistent over time, but the exact amount varies, based on production. For example, companies have to pay the electricity bill every month, but how much they have to pay depends on the scale of production. For instance, during months of heavy production, the bill goes up; during the off season, it goes QuickBooks down.

- Before the beginning of any accounting year, it is determined to estimate the level of activity and the amount of overhead required to allocate the same.

- This calculation helps companies in budgeting and cost management by allocating indirect costs to specific products or projects before they are actually incurred.

- Now that we understand how to group the components of manufacturing, let’s examine the different factors that affect the cost of manufacturing.

- It’s usually more cost-effective to buy in bulk for common raw materials that are used often, but this is a substantial investment that may not be recouped for a long time.

- For businesses in manufacturing, establishing and monitoring an overhead rate can help keep expenses proportional to production volumes and sales.

- At Finance Strategists, we partner with financial experts to ensure the accuracy of our financial content.

- Establishing the overhead allocation rate first requires management to identify which expenses they consider manufacturing overhead and then to estimate the manufacturing overhead for the next year.

- For example, you can use the number of hours worked or the number of hours machinery was used as a basis for calculating your allocated manufacturing overhead.

- This not only helps gauge what price the market is willing to bear but also identifies pricing trends that may indicate the need for further cost reductions or efficiency improvements in their own operations.

- The estimated or budgeted overhead is the amount of overhead determined during the budgeting process and consists of manufacturing costs but, as you have learned, excludes direct materials and direct labor.

- There are several reasons why businesses need to calculate a predetermined overhead rate.

But make sure to distinguish the labor rate from the wage paid to the worker. The labor rate is the employee’s base pay plus overhead, which includes taxes, insurance, and benefits. With semi-variable overhead costs, there will always be a bill (a fixed expense), but the amount will vary (a variable expense). Understanding these formulas allows businesses to budget for overhead, set predetermined rates, analyze variances, and adjust rates accordingly.